The Role of Optical Measurement Equipments beforehand Metrology Strategies

Optical measurement systems have changed width, bringing a degree of precision that was as soon as unimaginable. As you discover better, you'll discover just how these systems are shaping the future of dimension and top quality control.

The Development of Width: A Historic Viewpoint

As you explore the background of assessment, you'll discover that its advancement shows humankind's mission for precision and standardization. From ancient civilizations using body parts as devices of measurement to the growth of standardized weights and procedures, each step shows our desire for accuracy. The Egyptians built the pyramids using exact dimensions, while the Romans progressed design with their advanced measuring devices.

Throughout the Renaissance, clinical breakthroughs changed the focus toward a lot more empirical approaches, leading the way for modern-day assessment. The intro of the metric system in the late 18th century noted a considerable landmark, establishing universal requirements. Throughout the 20th century, technological innovations better changed assessment, enabling highly exact dimensions in numerous fields.

Today, width remains to advance, integrating digital innovation and automation. This background highlights not just the value of measurement however also our unrelenting search of boosting precision and uniformity in our increasingly complicated globe.

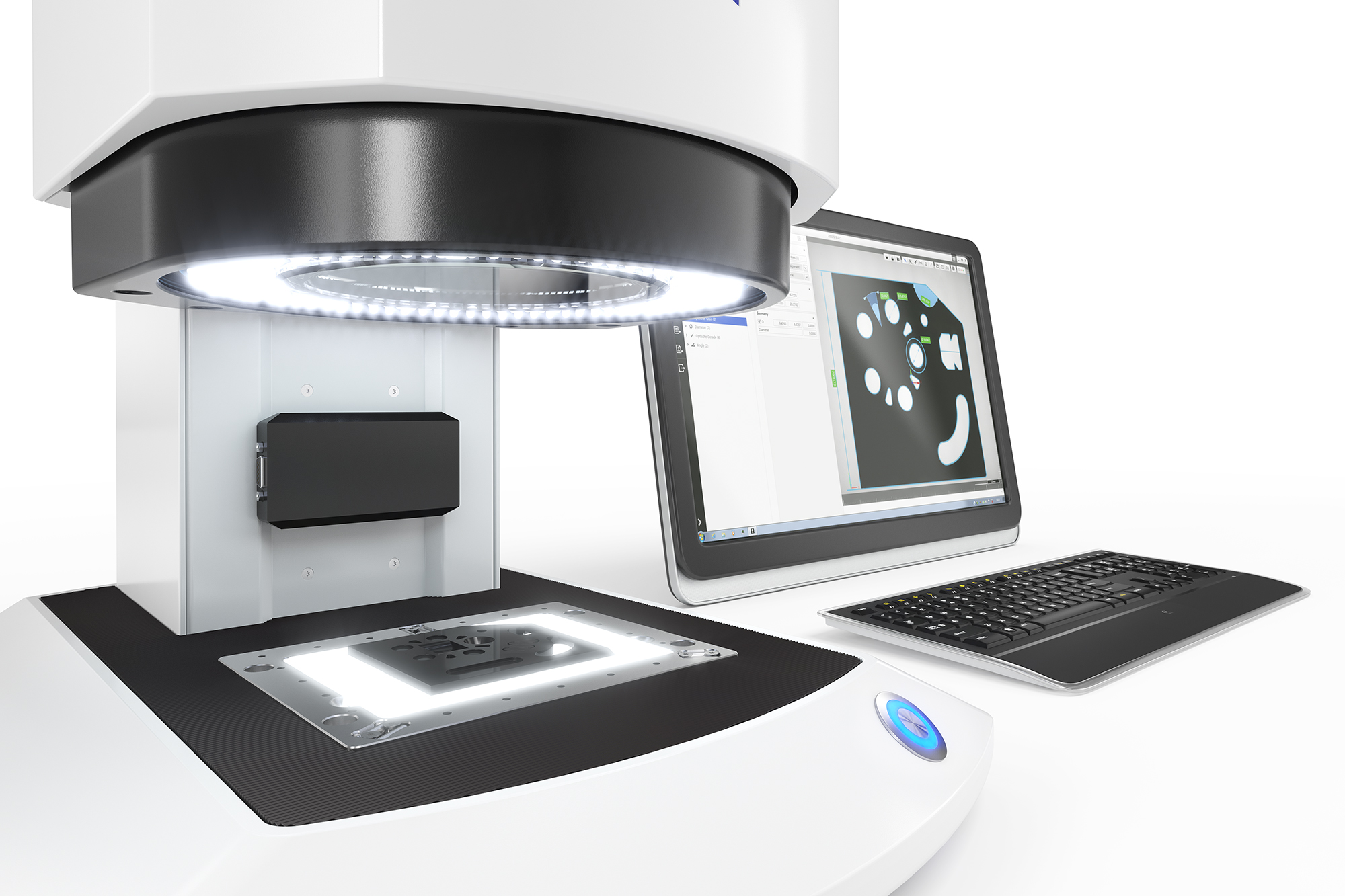

Principles of Optical Dimension Systems

Comprehending the concepts behind optical measurement systems is necessary for exact cause metrology. You'll intend to take into account basic optical principles, measurement precision elements, and effective system calibration techniques. Each of these elements plays a crucial duty in guaranteeing your measurements are exact and dependable.

Fundamental Optical Principles

While checking out optical dimension systems, you'll come across fundamental optical concepts that form the foundation of precise information procurement. Light acts in foreseeable methods, and understanding these actions-- like refraction, representation, and diffraction-- is vital for reliable measurements. By understanding these principles, you'll be geared up to leverage optical technologies efficiently, leading the means for innovations in metrology and guaranteeing your measurements are both trustworthy and repeatable.

Measurement Precision Aspects

To accomplish high measurement accuracy in optical systems, a number of aspects enter play, affecting the dependability of your outcomes. First, the high quality of the optical components matters substantially. Premium lenses and detectors minimize aberrations and sound, guaranteeing your measurements are accurate. Second, environmental problems like temperature level and moisture can affect measurements, so preserving a secure atmosphere is essential. Third, the positioning of the optical system is vital; even minor imbalances can lead to considerable errors. Lastly, the wavelength of light utilized impacts the resolution and accuracy of your dimensions. By dealing with these elements, you can boost the overall performance of your optical measurement systems, bring about more precise and dependable lead to your assessment applications.

System Calibration Strategies

Accomplishing high measurement accuracy is only component of the formula; appropriate system calibration methods are similarly important in optical measurement systems. Next, use well-known dimensions to confirm the system's output and make necessary adjustments. With these techniques, you'll enhance the integrity of your optical dimension system.

Secret Technologies Behind Optical Measurement

Optical dimension systems depend on a number of key technologies that enhance precision and effectiveness in metrology. One essential technology is interferometry, which makes use of the disturbance of light waves to measure small displacements and surface area irregularities with severe accuracy. You'll also locate laser scanning systems, which catch detailed 3D information of objects promptly, making them very useful for dimensional evaluation.

Additionally, CCD and CMOS sensing units play a significant role in converting light into electric signals, enabling high-resolution imaging and precise dimensions. Advanced algorithms for picture processing additionally improve dimension accuracy by examining data in actual time, filtering out noise and boosting features.

Lastly, fiber optics supply flexibility and the capability to gauge in challenging settings while maintaining signal stability. By leveraging these technologies, you can accomplish premium cause your assessment jobs, guaranteeing that your dimensions are both reputable and exact.

Applications of Optical Dimension in Industry

As markets progressively require precision and efficiency, the applications of optical measurement systems have actually come optical measurement systems to be vital across different fields. In manufacturing, these systems help you keep an eye on measurements and resistances in real-time, making certain quality control without lengthy hands-on checks. In the vehicle sector, optical dimensions aid in aligning components with precision, enhancing security and performance.

In electronics, you're utilizing optical techniques to check min attributes on motherboard, identifying defects that could lead to failures. The aerospace sector gain from non-destructive testing techniques, allowing you to evaluate materials and elements without jeopardizing their integrity.

Optical measurement also plays an important role in fabrics, making certain textile measurements fulfill precise specs. optical measurement. With their capacity to supply high-resolution data rapidly, these systems empower you to make enlightened choices, enhance processes, and ultimately drive innovation throughout your market

Enhancing Accuracy and Performance in Dimensions

When you consider boosting precision in measurements, accuracy in your measurement techniques is essential. By simplifying these procedures, you can achieve quicker outcomes without compromising quality. Allow's check out how taking on sophisticated optical dimension systems can raise both accuracy and performance in your work.

Accuracy in Dimension Techniques

Accuracy in dimension strategies is essential for achieving dependable results in assessment, particularly considering that little inconsistencies can lead to considerable mistakes. By using sophisticated optical measurement systems, you can enhance the accuracy of your measurements. In enhancement, precise dimensions permit you to keep high quality control, making sure that products fulfill rigorous requirements.

Improving Measurement Processes

To enhance precision and performance in dimensions, enhancing your measurement processes is essential. Beginning by taking on optical measurement systems that provide real-time information, lowering the moment invested in manual recording. These systems often incorporate effortlessly with existing software application, allowing you to automate information collection and evaluation.

Next, systematize your measurement protocols. By applying constant procedures, you lessen variability and boost repeatability. Do not forget to regularly adjust your equipment to assure its precision.

The Effect of Optical Dimension on Research and Development

As researchers venture to press the borders of innovation, optical measurement systems have ended up being crucial devices in the advancement procedure. These systems offer you with exact, real-time information that boosts your capacity to analyze complex materials and structures. In various fields, from biotechnology to aerospace, you depend on optical measurements to enhance styles and enhance item performance.

With high-resolution imaging and non-contact techniques, you can reduce sample disturbance, enabling more accurate results. This capacity to record minute information increases your R&D cycle, allowing you iterate designs quickly and efficiently. Optical measurement cultivates cooperation throughout self-controls, as the data created is usually quickly interpretable and shareable.

Eventually, integrating optical dimension systems right into your research study not only enhances performance however also grows your understanding of the sensations you study. By leveraging these advanced strategies, you're much better equipped to introduce and stay ahead in an affordable landscape.

Future Trends in Optical Dimension Solutions

With the rapid innovation of innovation, you're most likely to see considerable shifts in optical dimension systems that will redefine their application throughout various sectors. You'll discover an approach enhanced automation and combination of expert system, permitting for real-time data evaluation and enhanced precision. Miniaturization is one more trend; small devices will allow measurements in tighter rooms, making them suitable for fields like aerospace and biomedical applications.

Expect to see systems that can run in tough settings, providing reputable dimensions in severe problems. As these modern technologies converge, you'll find that optical measurement systems not only improve precision however likewise enhance operations, inevitably driving innovation and efficiency in your projects.

Frequently Asked Questions

How Do Optical Measurement Solutions Contrast to Conventional Measurement Techniques?

Optical measurement systems provide higher precision and faster results compared to traditional techniques. You'll find they capture even more information factors properly, reducing human mistake and increasing dependability, making them a preferred choice in various applications.

What Industries Benefit Most From Optical Dimension Equipments?

You'll locate markets like aerospace, automobile, and electronics profit most from optical dimension systems. These markets depend on accurate measurements to assure top quality and performance, enhancing performance and lowering expenses through innovative modern technology.

Are Optical Measurement Equipments Expensive to Carry Out?

Optical dimension systems can be costly to implement, however their precision and effectiveness frequently warrant the cost. Spending in such technology can cause significant long-lasting financial savings and improvements in top quality across different applications.

What Abilities Are Required to Operate Optical Dimension Systems?

To run optical dimension systems, you'll need solid logical skills, interest to information, and proficiency in software application devices. Familiarity with optics and an understanding of measurement concepts will certainly also improve your efficiency and efficiency.

Exactly How Do Ecological Variables Affect Optical Measurements?

Ecological variables like temperature, air, and moisture high quality can distort optical dimensions. You'll notice variants in accuracy due to light interference or refraction. optical measurement system. Keeping secure problems is essential for specific and trusted optical dimension outcomes

Verdict

In summary, optical dimension systems are reinventing assessment by providing unparalleled accuracy and efficiency. As you discover future patterns, you'll see how the assimilation of AI and automation will certainly continue to boost measurement techniques, driving advancement and improving top quality control.

Accomplishing high measurement precision is only component of the equation; appropriate system calibration techniques are just as crucial in optical measurement systems.When you assume regarding boosting accuracy in dimensions, precision in your dimension methods is important. By making use of advanced optical dimension systems, you can enhance the precision of your measurements.To improve accuracy and effectiveness in measurements, enhancing your measurement processes is essential. Exactly How Do Optical Dimension Systems Contrast to Traditional Measurement Techniques?